TECHNOLOGY & PRODUCTS技術・製品紹介

HOME > TECHNOLOGY & PRODUCTS > Product List > Yoshinogawa Electric Wire & Cable

- TECHNOLOGY & PRODUCTS

- Product List

- Standard Series

- Tough Slim Series

- Interface Cable

- Flexible Coaxial Cable

- Yoshinogawa Electric Wire & Cable

- Example of Composite Cables

- Example of Curling (coiling) cables

- Example of Self-Supporting Cables

- Example of Flat Cables

- Yoshinogawa Electric Wire & Cable's durability

- Kreston Cable

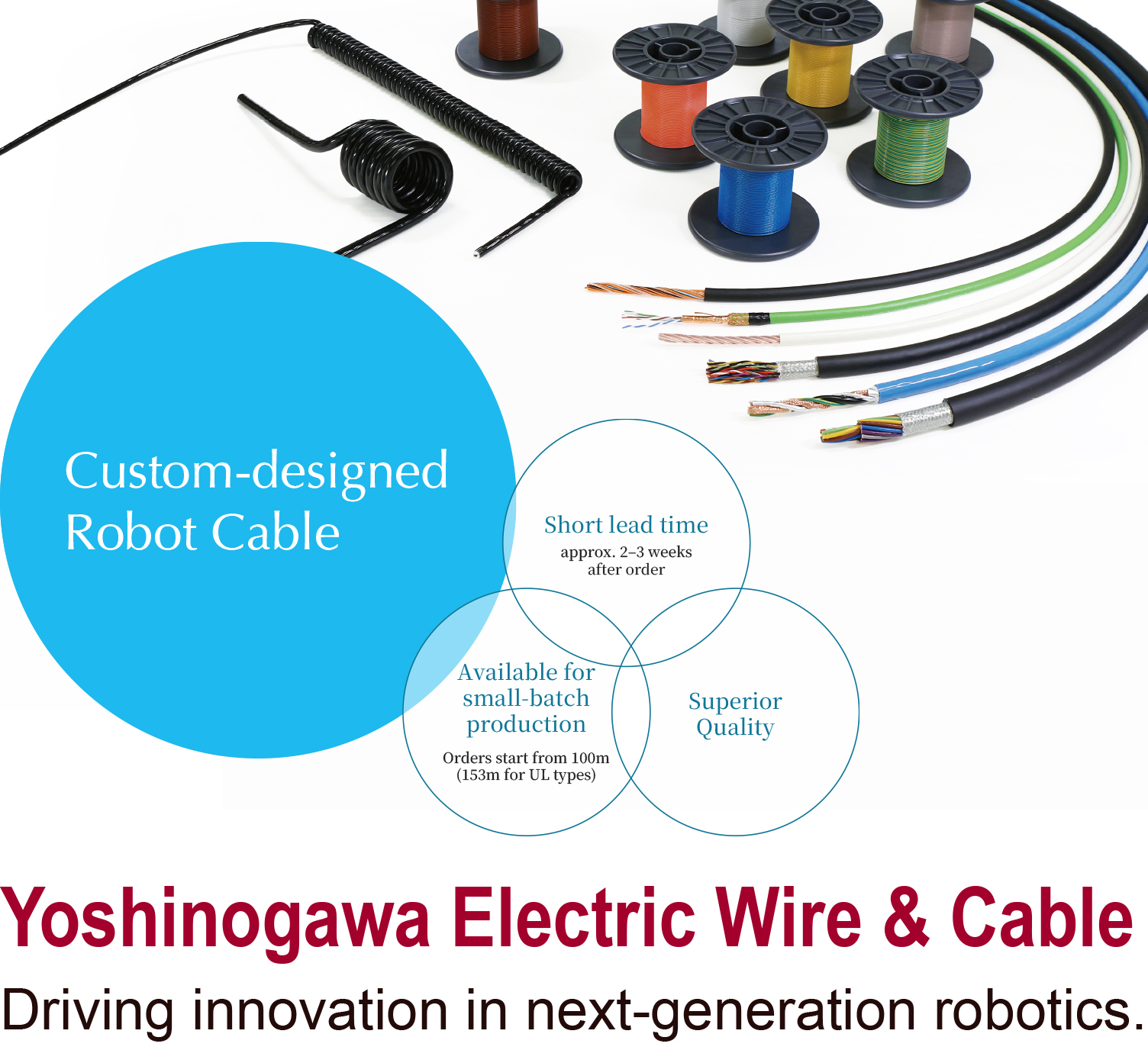

Yoshinogawa Electric Wire & Cable

Yoshinogawa Electric Wire & Cable is made with many excellent features,

perfect for the moving parts and robot wiring.

Great flexibility, bending or twisting durability, abrasion/heat/oil/chemical resistance,

we provide the best solution to meet your usage environment.

We respond to such requests!

- Durable and dependable cabling solutions.

- Organize and simplify your cable system.

- Easy wiring solutions.

- Cleanroom-compatible cable solutions.

- Chemical- and oil-resistant cable solutions.

- Highly flexible cable solutions.

- Eco-conscious cable solutions.

- Thinner cables, same number of cores.

Cables customized for your specific application.

- Specially designed custom cables

- Multi-functional composite cables (signal + power + tubing)

- Integrated flat cables

- Fused or bonded robot cables

- Coiled cables

- Coaxial cables

Compliant with RoHS 2 substance restrictions.※ Except when present as impurities or unintended unreacted by-products.

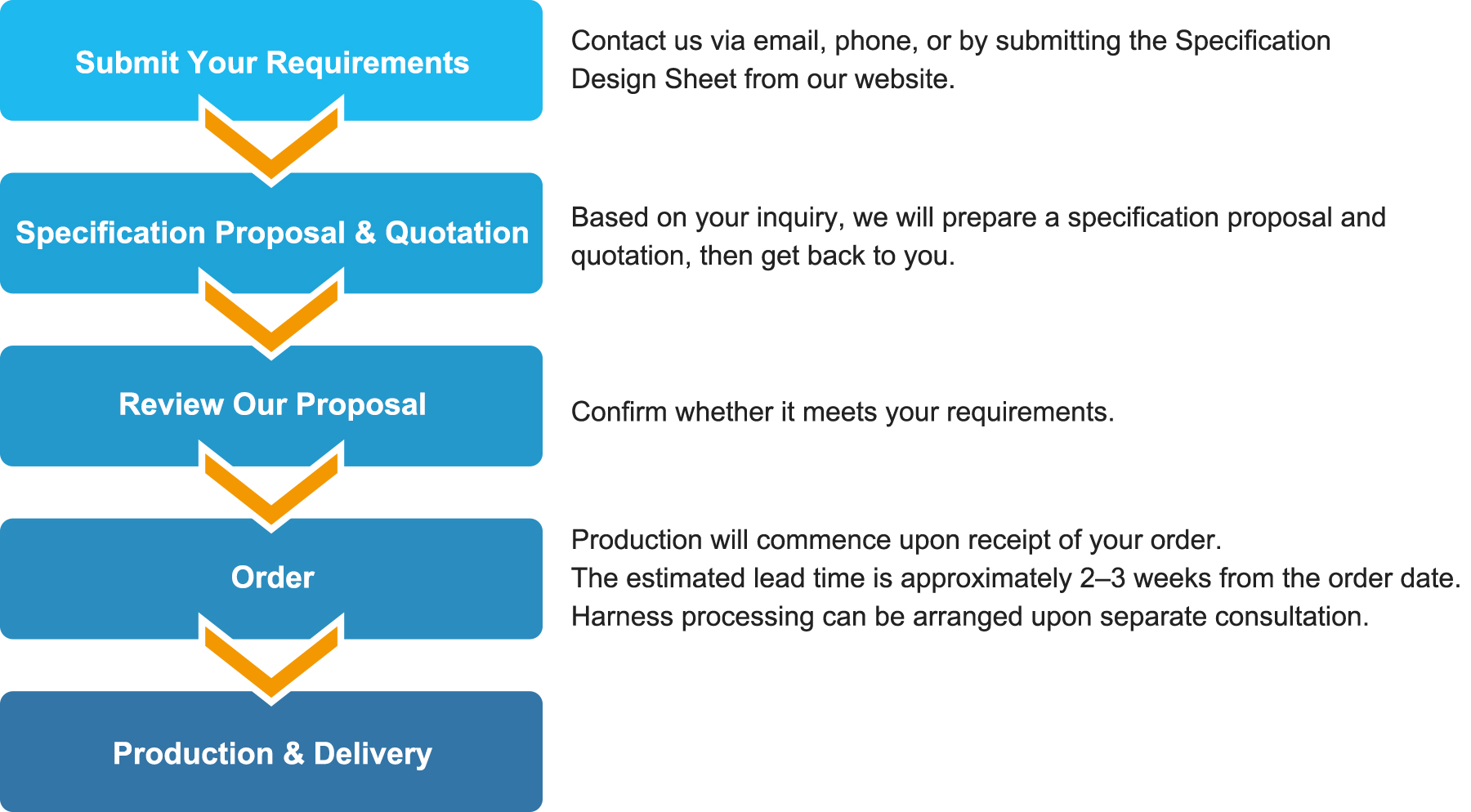

Process Flow: From Inquiry to Delivery

We propose the optimal cable specifications based on your intended use and environmental conditions.

Production begins only after you have approved the specification, quotation and delivery timeline.

If needed, we can also provide durability test data or samples of similar products

during the proposal stage.

Please feel free to consult us regarding design, quotation, or delivery details.

Yoshinogawa Electric Wire & Cable

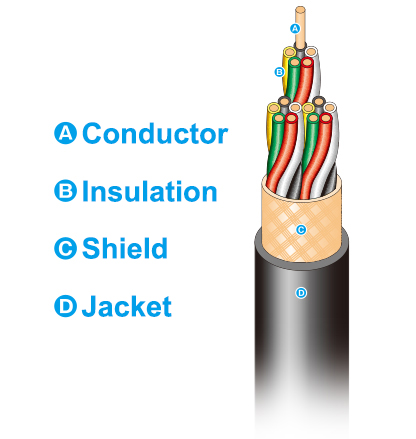

Custom orders available!

We provide custom-designed cables for dynamic use, selecting the ideal conductor, insulation and sheath materials, along with the appropriate core configuration and shielding type.

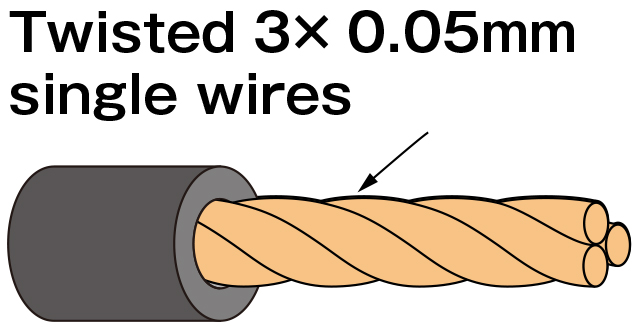

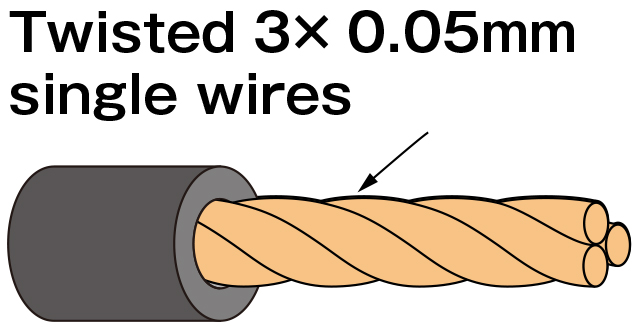

🅐 Conductor

Copper Alloy (S)

| Conducting Material | Tensile Strength (MPa) | 727 |

|---|---|---|

| Elongation (%) | 1.0 | |

| Electrical Conductivity (%) | 75 | |

| Structure |  |

|

| Tensile Strength (MPa) Characteristic | Special copper alloy material for higher durability based on its excellent mechanical properties. | |

Annealed Copper (A)

| Conducting Material | Tensile Strength (MPa) | 207 |

|---|---|---|

| Elongation (%) | 15.0 | |

| Electrical Conductivity (%) | 98 | |

| Structure |  |

|

| Tensile Strength (MPa) Characteristic | Twisted extra-fine copper alloy wire. Big sizes available. Suitable for both signal and power supply use. |

|

🅑 Insulator

ETFE(F)

| Tensile Strength (MPa) | 39.2 |

|---|---|

| Elongation (%) | 200 |

| Heat Resistance (℃) | 150 |

| Oil Resistance | ◎ |

| Flame Retardant | ◎ |

| Weather Resistance / Hydrolysis Resistance |

◎ |

| Durability | ◎ |

| Characteristic | Excellent electrical and physical property. 300~600V-capable. |

Polyester (E)

| Tensile Strength (MPa) | 39.2 |

|---|---|

| Elongation (%) | 500 |

| Heat Resistance (℃) | 120 |

| Oil Resistance | ○ |

| Flame Retardant | × |

| Weather Resistance / Hydrolysis Resistance |

△ |

| Durability | ○ |

| Characteristic | For signal cable use. Lower cost than ETFE. 100V-capable. |

🅒 Shield(S)

Braided Shield

Well-balanced structure for noise property and durability.

Spiral Shield

Superior in the flexure property.

Noise property is inferior to the braided shield.

Material

Copper alloy, annealed copper, foil yarn, and more.

※ We provide optimized material solutions tailored to various industrial applications.

🅓 Sheath

Polyurethane (U)

| Tensile Strength (MPa) | 29.4 |

|---|---|

| Elongation (%) | 400 |

| Heating Resistance (°C) | 80 |

| Oil Resistance | ○ |

| Flame Retardant | ○ |

| Characteristic | It maintains moderate hardness and is suitable for localized bending such as spatial bending. |

Lead-free PVC (V)

| Tensile Strength (MPa) | 10.0 |

|---|---|

| Elongation (%) | 120 |

| Heating Resistance (°C) | 105 |

| Oil Resistance | ○ |

| Flame Retardant | ◎ |

| Characteristic | Soft and heat resistant. Good slip properties, suitable for use in cable carriers. |

Etc : Depending on the application, polyester (E) and polyolefin (O) may also be used.

※ The figures in the table are representative values for each material.

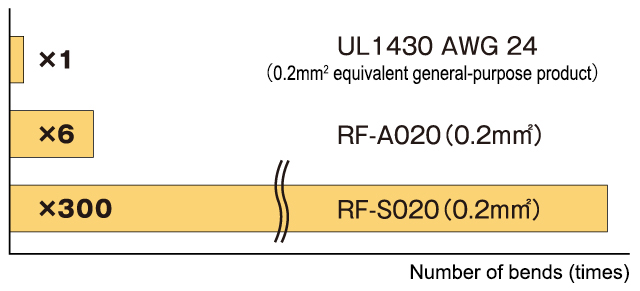

Comparison of durability at the core level

As an example of durability, we show comparative data from flexural fatigue tests. Please contact us for specific cable durability and test data.

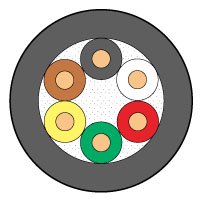

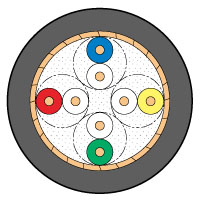

Cable Structure

Yoshinogawa Electric Wire & Cable is long-lasting.

Robot cables require durability for various types of movements,

but no any single cable is universally suitable for all motions.

We design cables tailored to our customers' specific movement needs.

Examples

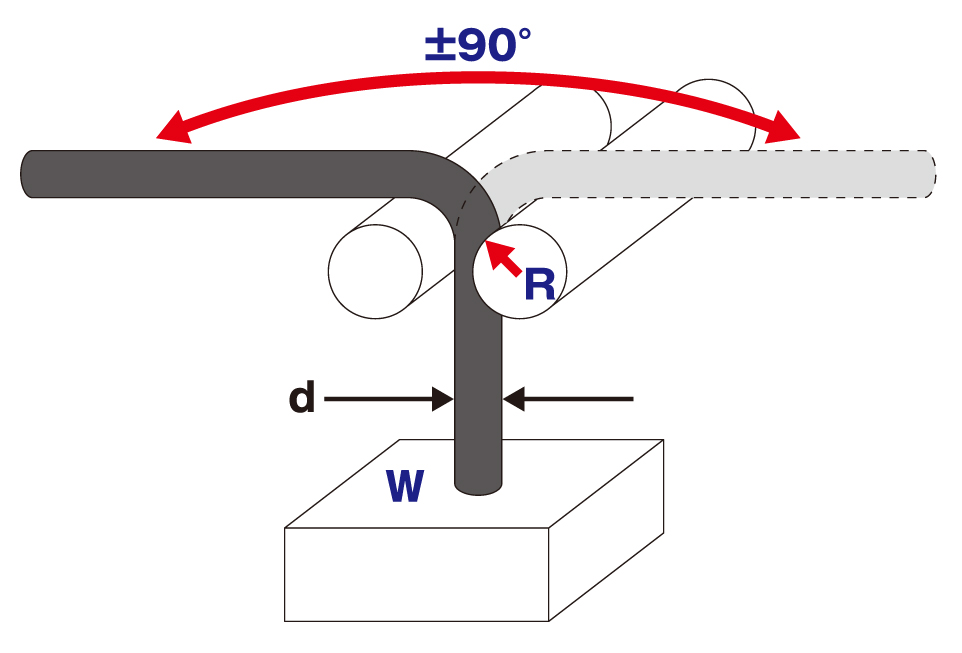

For Bending Motion

Uses an elastic sheath material to reduce repeated stress on the cable.

Designed to alleviate localized stress concentration.

Tensile load: W = 500g

Bending radius: R = 20mm

Durability test: Withstood 5 million twisting cycles

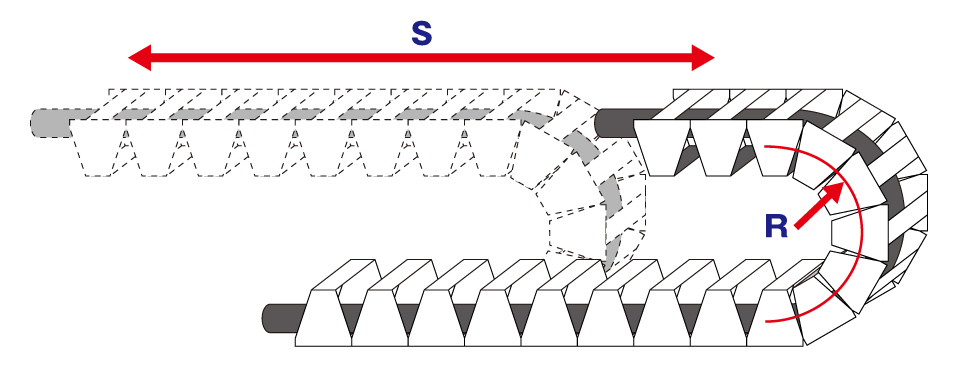

For U-Bending Motion

A soft sheath material is used to reduce friction between cables and with its guide holder

The bending radius (R) is also important being considered

Stroke (S) = 500㎜

Radius (R) = 50㎜

Durability test: Withstood 20 million U-bending cycles

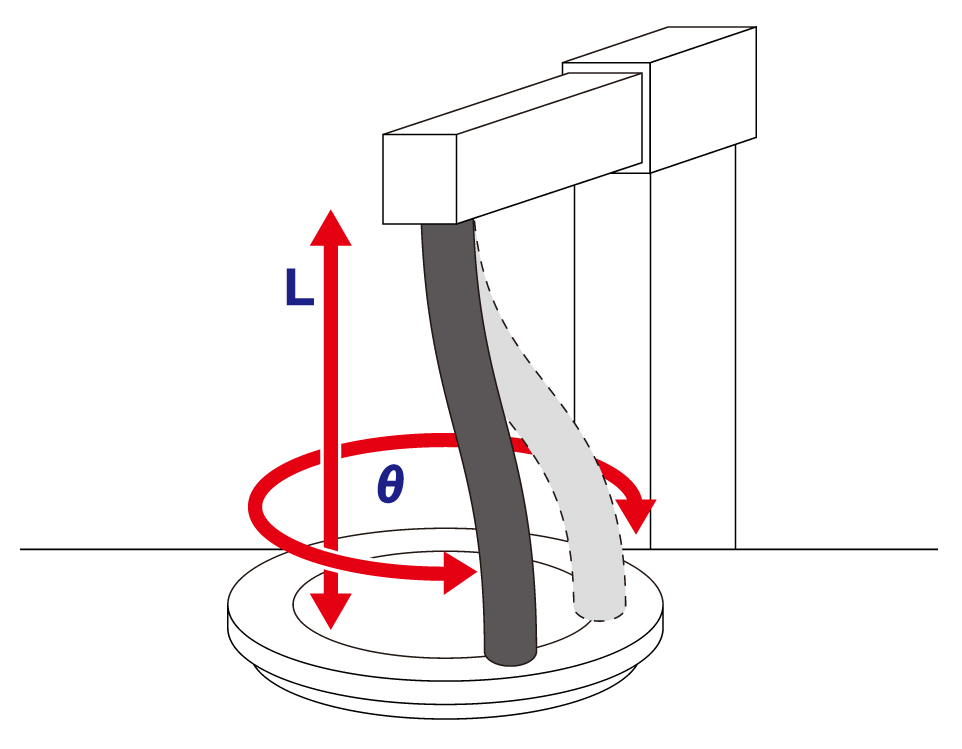

For Twisting Motion

Among movable conditions, where cables are subjected to significant stress, the cable is designed with a twisted structure that minimizes the torsional stress applied to the conductor.

Twisting θ = ±280°

Stroke (L) = 700㎜

Durability test: Withstood 20 million Twisting Motion cycles

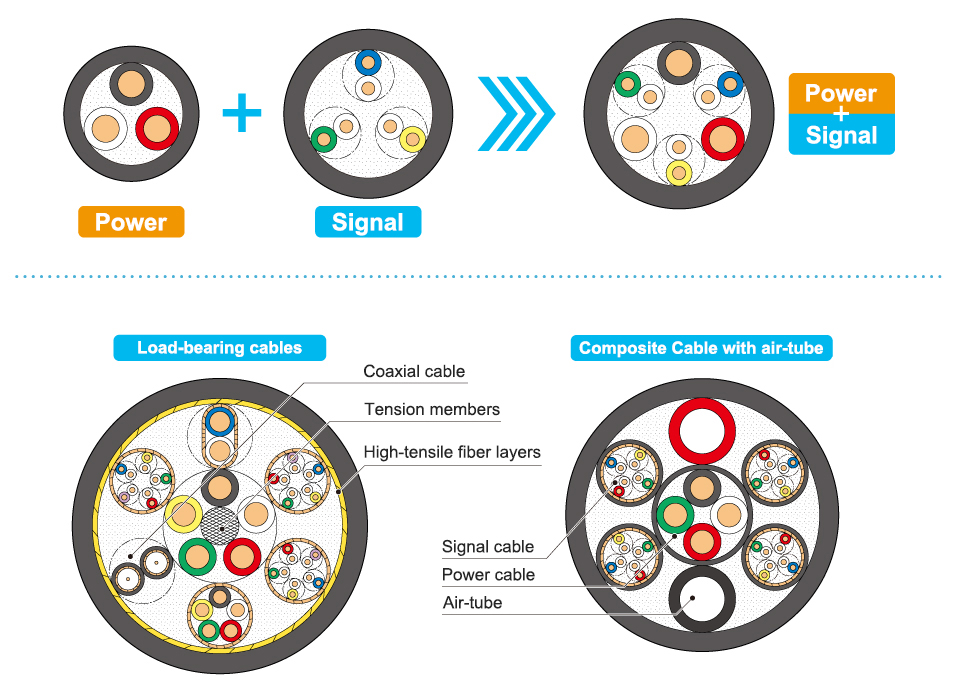

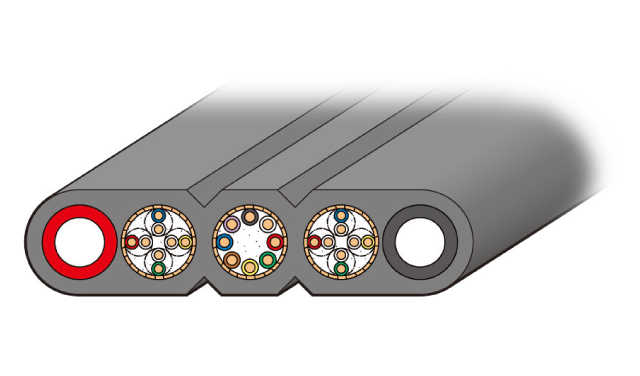

Example of Composite Cables

Features

We can integrate different types of wires , including signal wires, power lines, coaxial cables, tubes, compensating copper wires, and tension members into a single cable.

Application

- Perfect for narrow spaces.

- Cases where the cable must support its own tension, such as in logistics cranes.

- Wiring requiring cable self-support.

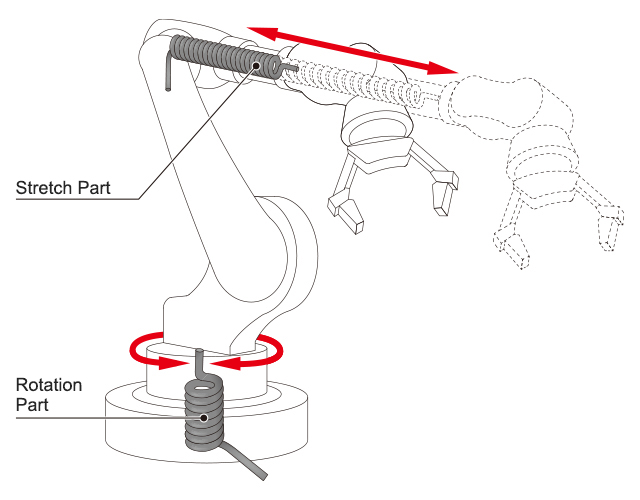

Example of Curling (coiling) cables

- Rotational absorption

- Axis or Swivel

- High-Flex and High-Speed

We offering curling (coiling) processing on cables of various sizes and core counts, including composite cables.

For cable sheath , we using polyurethane as material to we ensure long-term shape retention in addition to standard one.

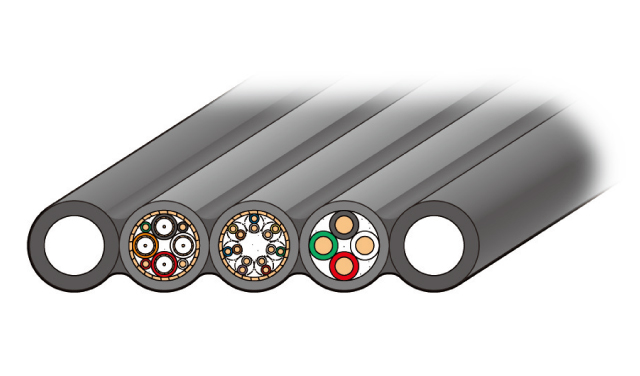

Example of Self-Supporting Cables

Features

Self-supporting cables integrate necessary power lines, signal lines, and air tubes into a single composite cable with controlled rigidity.

This design enables flex-free wiring in twisting and bending movements.

- Reduces weight and size

- Simplifies wiring work

Application

Ideal for applications requiring self-supporting wiring, such as SCARA robots and Cartesian robots

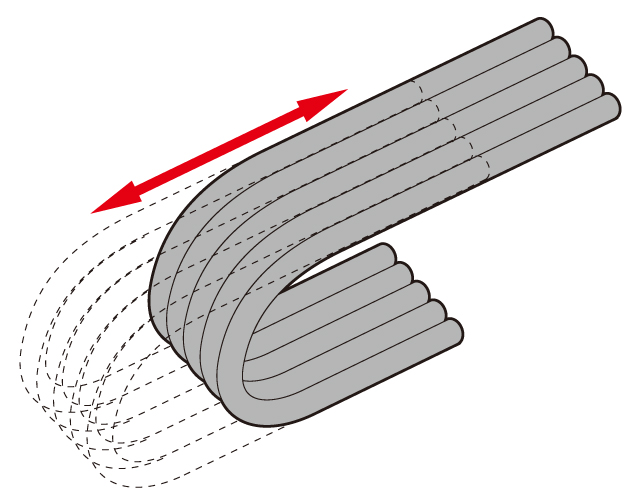

Example of Flat Cables

- Reduces stress

- Improved durability

- Longer lifespan

Using flat cables in cable carriers eliminates the friction between individual round cables, reducing sheath abrasion and dust generation.

Adhesive-Bonded

- Allowing modification of specific sections as needed such as branching or 90-degree bends during installation.

- Ideal for applications such as wiring consolidation for XY stages.

Fully Molded Types

- Compatible with long-length applications.

- More cost-effective than adhesive types.

Yoshinogawa Electric Wire & Cable's durability

Yoshinogawa Electric Wire & Cable's durability is based on a wealth of experience, enabling us to design cables that are optimally suited to our customers' usage conditions.

Furthermore, we conduct durability and evaluation tests on actual cables in accordance with customer requests.

Flame retardant / UL-approved

Flame retardant test equipment

(JIS Standard)

UL-approved AWM (ETFE insulation, PVC sheath)

| Rating | |

| STYLE 20921 | 105℃, 300V, VW-1 |

| STYLE 20949 | 105℃, 600V, VW-1 |

| STYLE 20276 | 80℃, 30V, VW-1 |

UL-approved AWM (ETFE insulation, polyurethane sheath)

| Rating | |

| STYLE 20233 | 80℃, 300V, VW-1 |

| STYLE 20234 | 80℃, 600V, VW-1 |

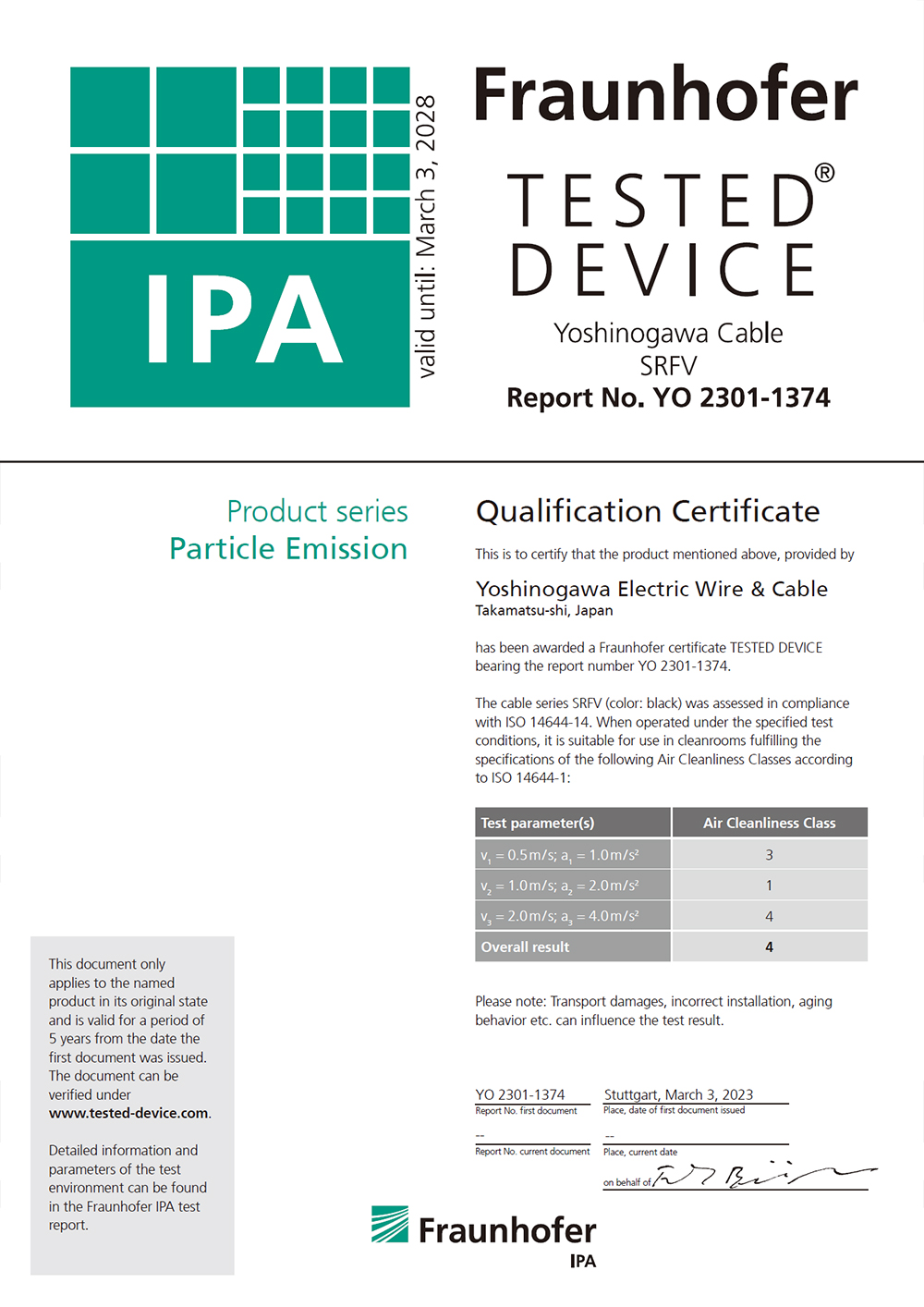

IPA Certification