TECHNOLOGY & PRODUCTS技術・製品紹介

HOME > TECHNOLOGY & PRODUCTS > Product List > Yoshinogawa Electric Wire & Cable

Yoshinogawa Electric Wire & Cable

Features

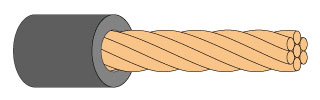

Yoshinogawa Electric Wire & Cable is made with many excellent features, perfect for the moving parts and robot wiring.

Great flexibility, bending or twisting durability, abrasion/heat/oil/chemical resistance, we provide the best solution to meet your usage environment.

From the material of conductor, insulator, shield and jacket (sheath) to the configuration of the cable, our design and proposal always satisfy every customer.

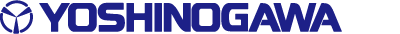

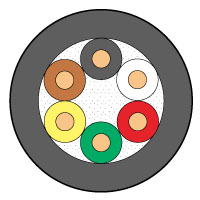

- Fine Coaxial cable

- Flexible Coaxial Cable

- Interface cable

- Composit cable

Durability

With our profound experience and database, to estimate the lifetime of Yoshinogawa Electric Wire & Cable with certain of conditions is possible. Durability evaluation test according to customer's conditions or applications is also available.

Materials

Conductor

If the tables below cannot be showed fully, please scroll the reel to view the rest of the items.

| Conducting Materials | Structure | |||

|---|---|---|---|---|

| Material | Tensile Strength (MPa) |

Elongation (%) |

Electrical Conductivity (%) |

|

| Copper Alloy (S) | 727 | 1.7 | 75 |

(ex) S020 3/36/0.05

|

| Special copper alloy material for higher durability based on its excellent mechanical properties. Suitable for applying to harsh conditions such as higher acceleration, larger torsion angle and so on, including signal transmission use. |

||||

| Annealed Copper (A) | 207 | 15.0 | 98 |

(ex) A075 7/22/0.08

|

| Twisted extra-fine annealed copper wire. Thicker sizes available. Suitable for both signal transmission and power supply use. |

||||

Insulator

If the tables below cannot be showed fully, please scroll the reel to view the rest of the items.

Sheath

If the tables below cannot be showed fully, please scroll the reel to view the rest of the items.

| Material | Tensile Strength (MPa) | Elongation (%) |

Heat Resistance (℃) |

Oil Resistance | Flame Retardant |

|---|---|---|---|---|---|

| Polyurethane (U) | 29.4 | 400 | 80 | 〇 | 〇 |

| High-Elasticity PVC (V) | 9.8 | 120 | 100 | 〇 | ◎ |

- High-Elasticity PVC is lead-free. (JGPSSI definition)

- Polyester (E) or Polyolefin (O) is also available as sheath materials.

Shield

If the tables below cannot be showed fully, please scroll the reel to view the rest of the items.

| Braided Shield | Well-balanced structure for noise property and durability. |

|---|---|

| Spiral Shield | Superior in the flexure property. Noise property is inferior to the braided shield. |

| Material | Copper Alloy Annealed Copper. Foil yarn is also available. |

- Pair shield

- Overall shield

- Pair shields with an overall shield

- Dual shield